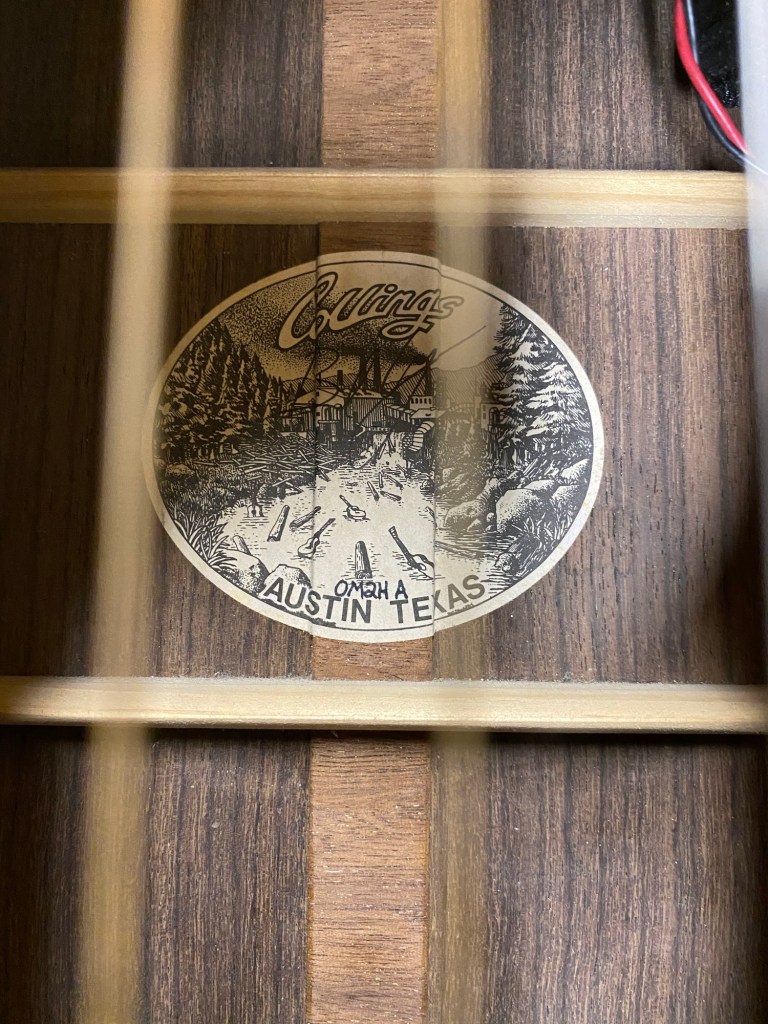

Custom Job took on the repair, cleaning and set up of a gorgeous Collings OM2H A recently. The guitar was purchased from a gigging player by a player/collector in the area. Overall, it was in fine condition aside from some fret dents, oxidization, and a dirty fretboard.

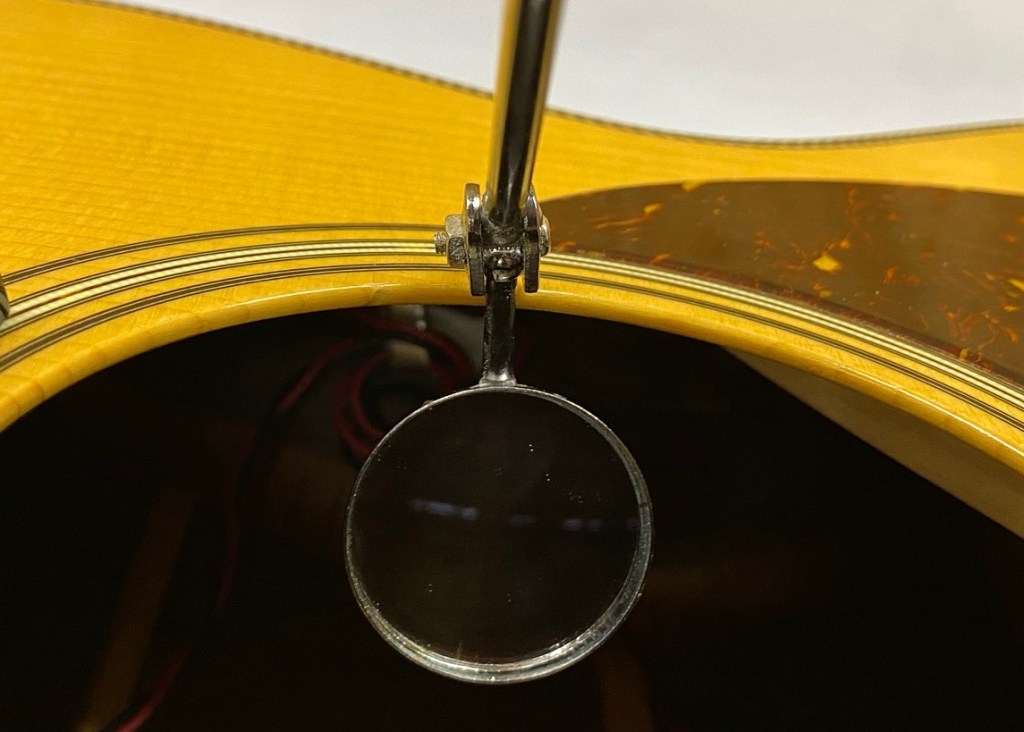

The main concern however, was a crack in the side running from the lower to upper bouts.

The crack had not yet reached the braces and not too much of the nitrocellulose had chipped short of at the point of impact. Unfortunately, at that point of impact there was some cross grain splitting so, four cleats were made of Indian rosewood, one for each end of the crack, one for dead center (all run cross grain) and one for the point of impact (run cross grain to the impact split, diagonal to the grain of the side). These were installed after working the grain back in place with rare earth magnets to hold everything tight while they cured

Afterwards, the side was lightly clamped and wicked with thin superglue until the crack was sealed then a coat of medium super glue was applied to be polished down even with the nitro finish.

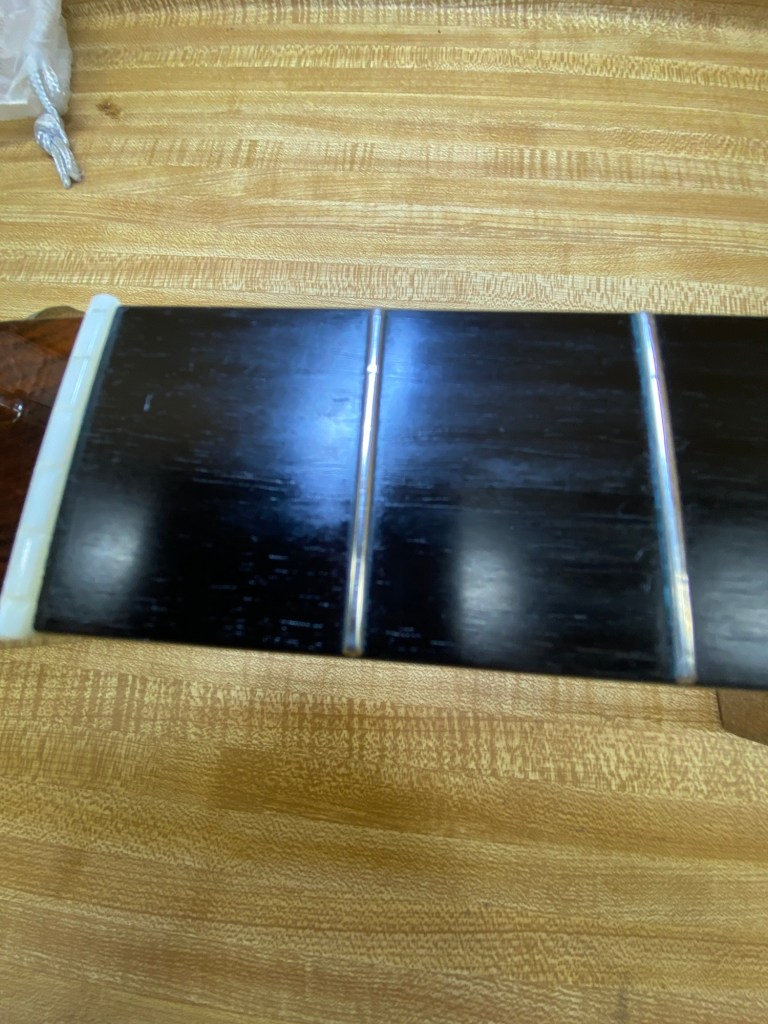

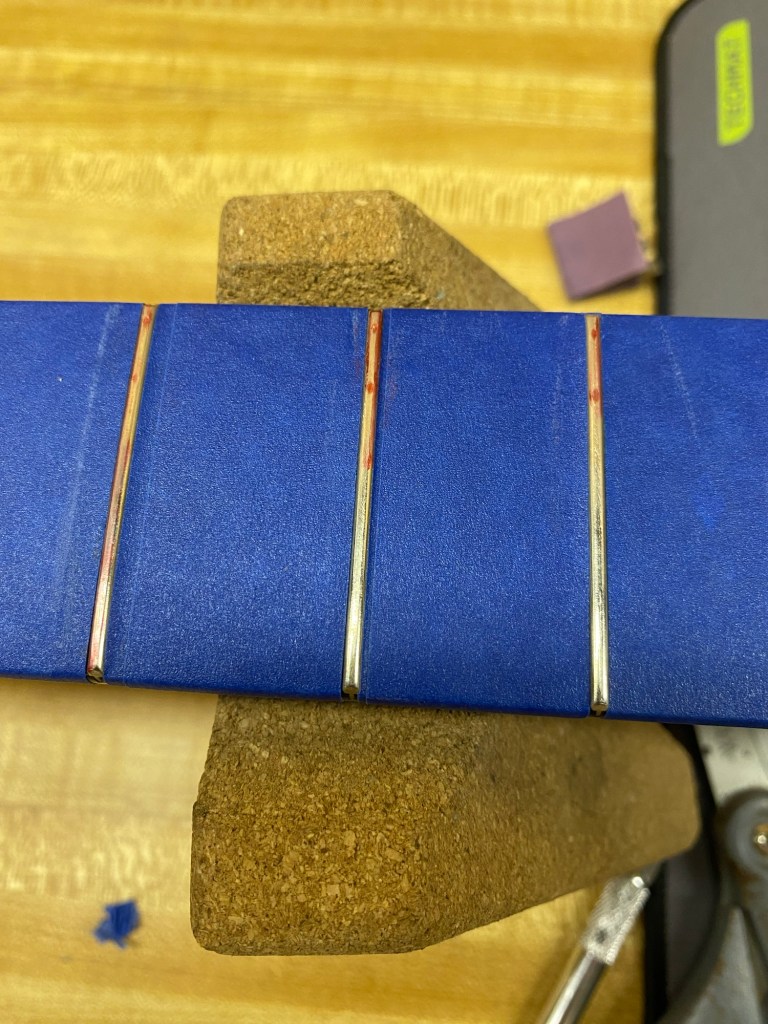

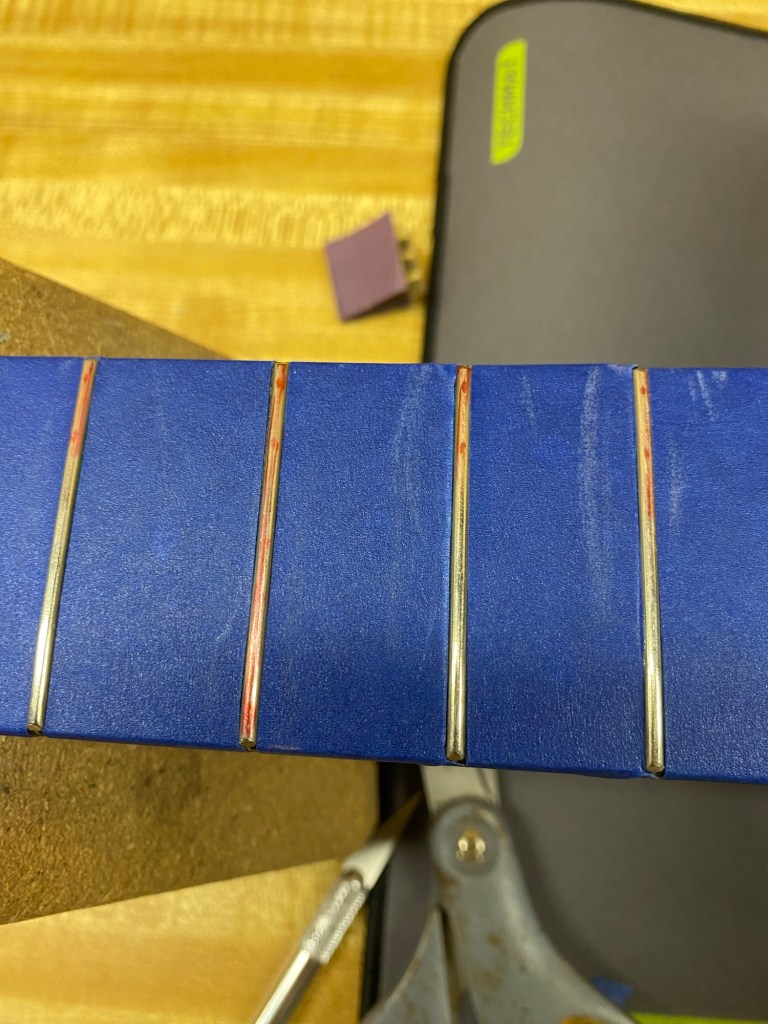

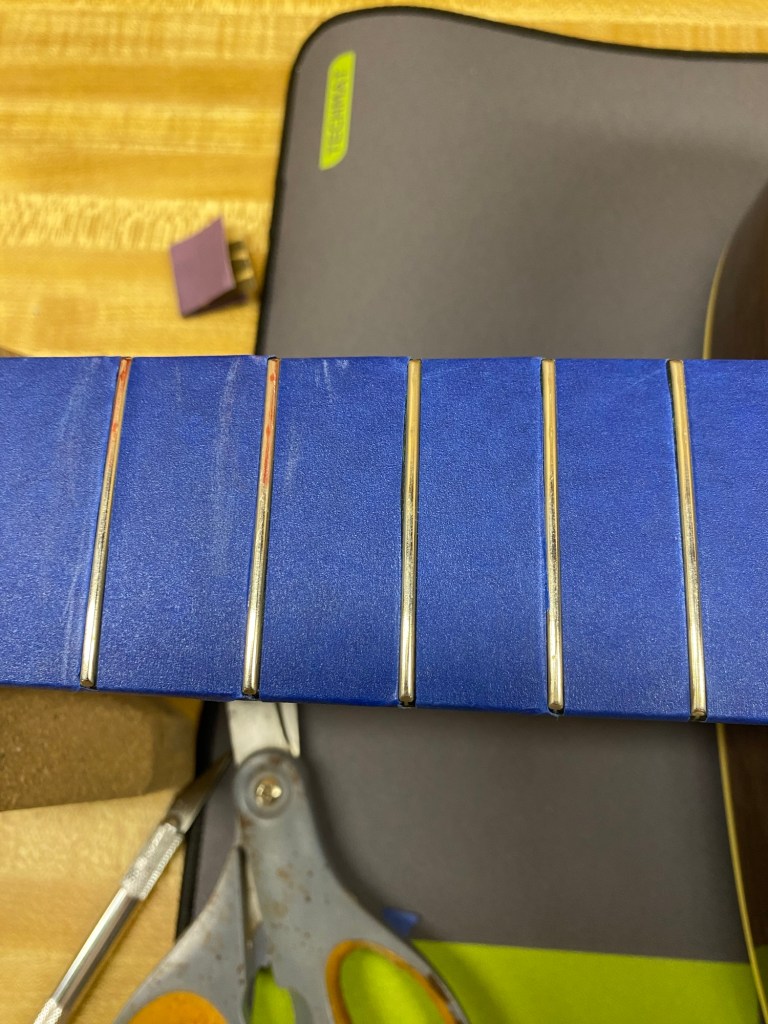

Upon cleaning the fretboard, a good deal of dents and wear became apparent on the frets. After masking, I ran a red sharpie over the frets and wiped it off with a blocked rag to expose the dents.

Honestly, had it been my guitar or if the actual fret material had been much lower, I’d have opted to level the frets, crown, dress and polish but that seemed like a bit too aggressive a path to take on a guitar that frankly already played remarkably well. Also, for whatever reason, the frets with the dents all seemed to coincide with frets that felt raised.. they weren’t popped but rather it seemed like a sort of on-the-go fret job had been performed at some point.

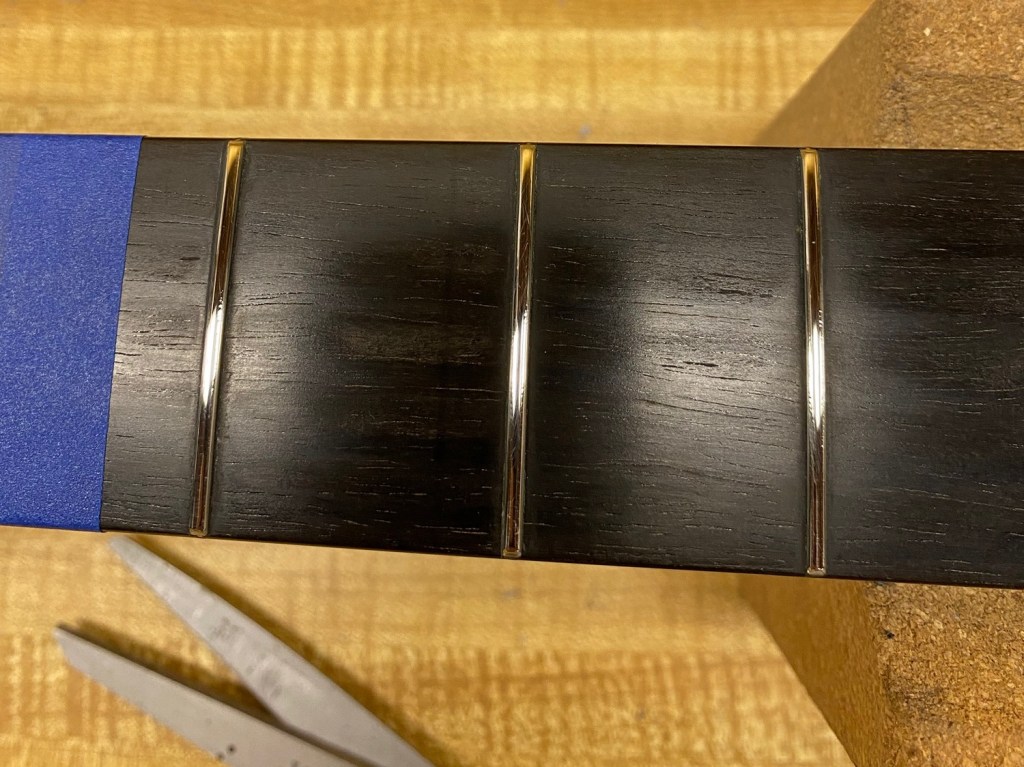

In the end, I opted to go the Fret Maestro route and individually crown, radius and level each effected fret then dress and polish from 600 to 3k grit followed by Menzerna GW16 then Blue Magic metal polish on a soft Dremel polishing disk. I finished up with Meguires Cleaner Wax.

When pulling the masking tape, the bone Nut came with it so that was centered and reaffixed. The whole fretboard was then conditioned.

The tuning machines were tight and the saddle was like new. Short of cleaning the rest of it, stringing it up and tuning it, that was about it.

I should say, I don’t have any experience owning a NICE acoustic guitar. I’ve played many, but this guitar, even before the repair blew my head off. Very articulate regardless of playing style. No sound choking when laying into it, no shrouding of voice or lack of projection when playing gently. The fretboard has the, I guess, stiffness one associates with an acoustic but there’s nothing unpleasant about it, no tripping over high strings, very little effort to fret anywhere on the neck. It’s aesthetically simple and largely exactly what you see when you close your eyes and think “acoustic guitar”. I’m stoked to have worked on it and hope my client has it in his collection for years to come.