This was a kit build for a Custom Job client. All I had to do was figure out how to put it together, how/where to get the stencils made, how best to apply and protect them, put it all back together and deliver it. Smooth, right?

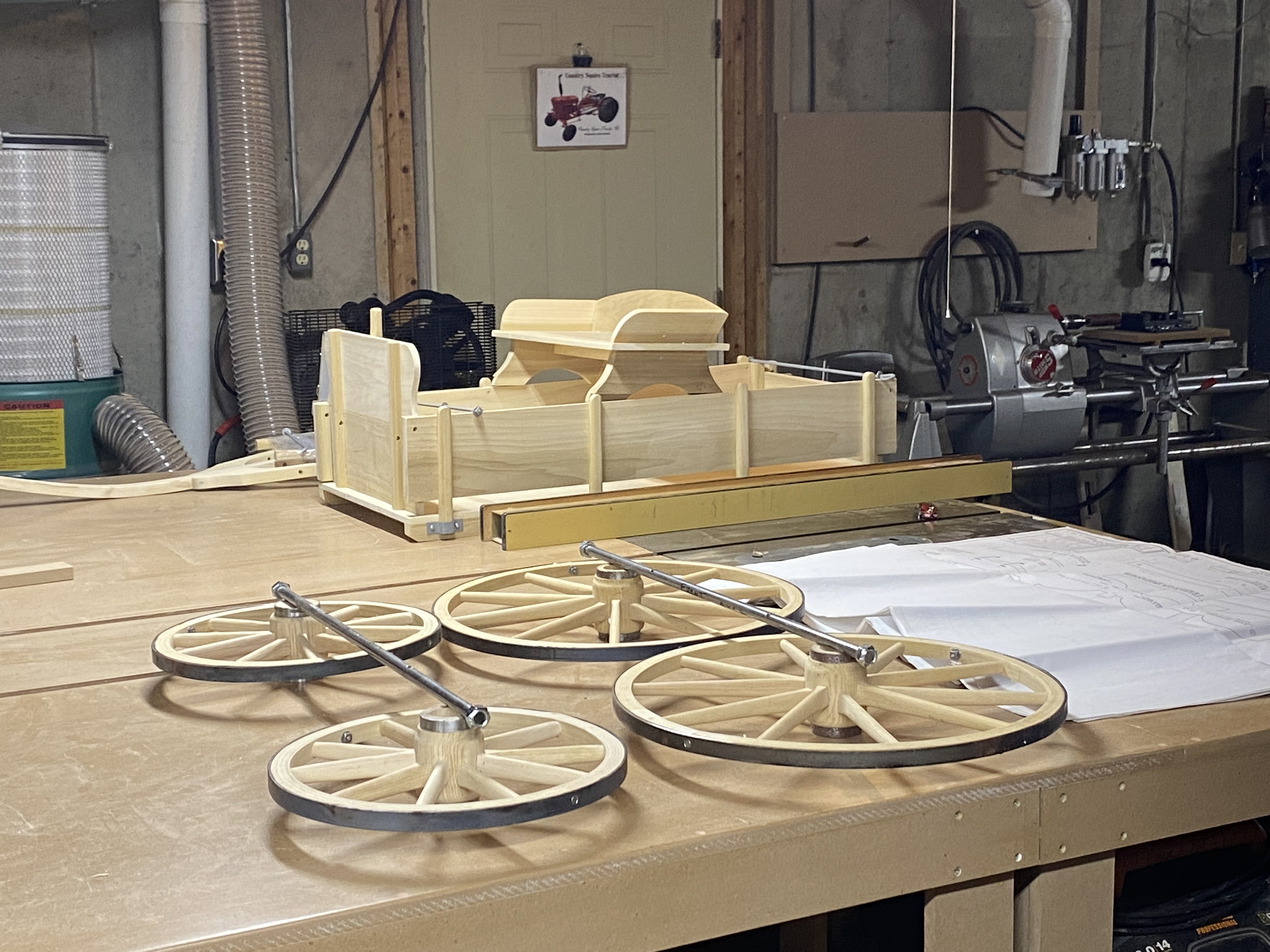

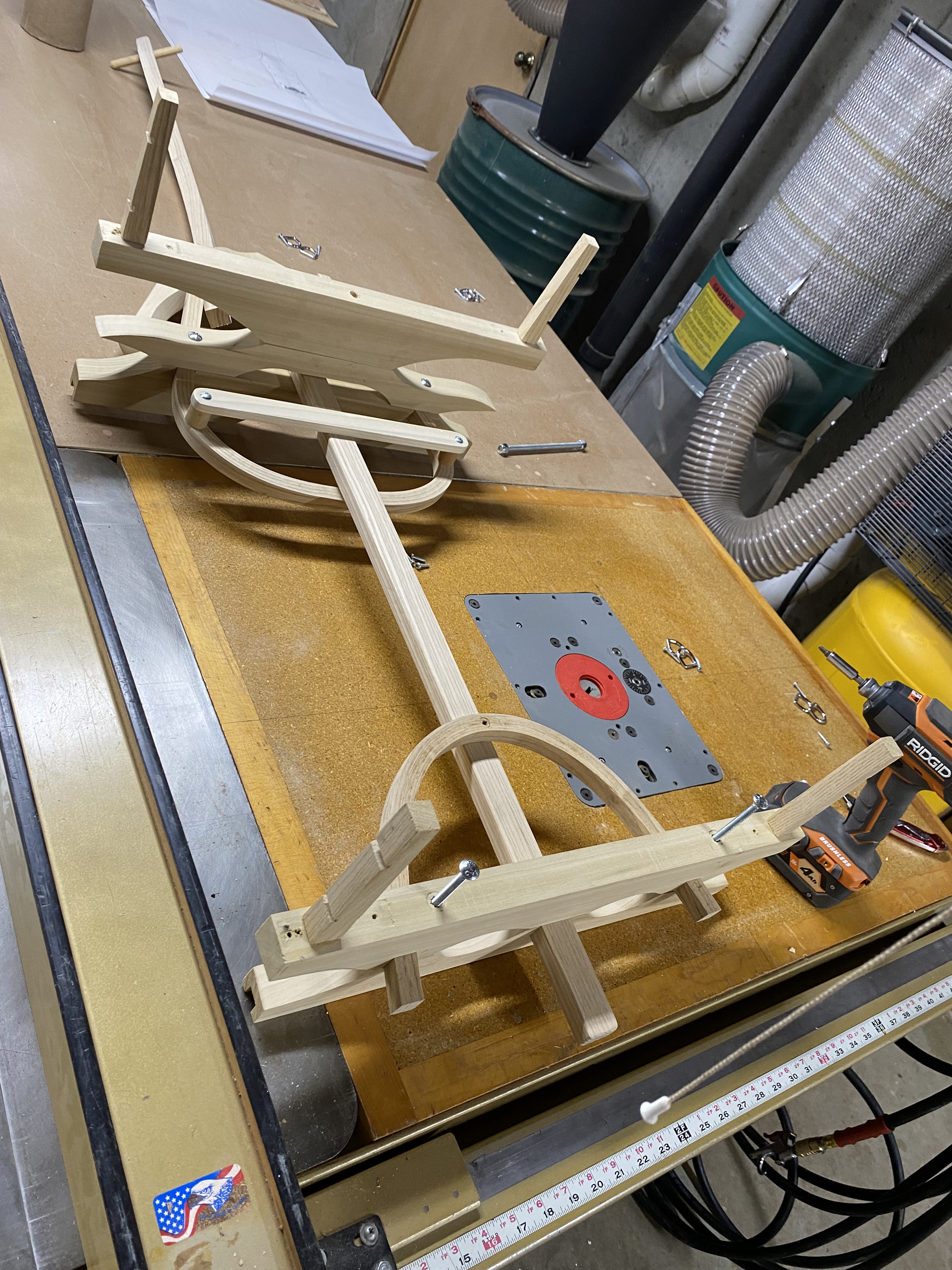

Actually, it was pretty smooth. The kit itself wasn’t terribly complex. My own issues with the fasteners used aside (a very diverse collection of Robertson, Phillips, Straight for screws .. lots of different sizes of all three .. used in places where a finishing brad would do …), It was a really well thought out kit and figuring out assembly was really quick work.

As I was saying, the use of two Robertson screws per board per structural intersection seemed heavy to me. I had to drive them a little deeper to accept filler. If I were to do it over, I’d sink them way down and dowel over them .. or request that the bottom not be assembled so it could be built a little more gingerly.

I’m not a huge fan of staining Poplar, it’s generally touchy wood and usually saved for paint. I ran into a bit of light scratching over time that took a lot of touchup that I usually don’t have to do with harder woods. But I feel like I got an even color, even across the varying species in the kit.

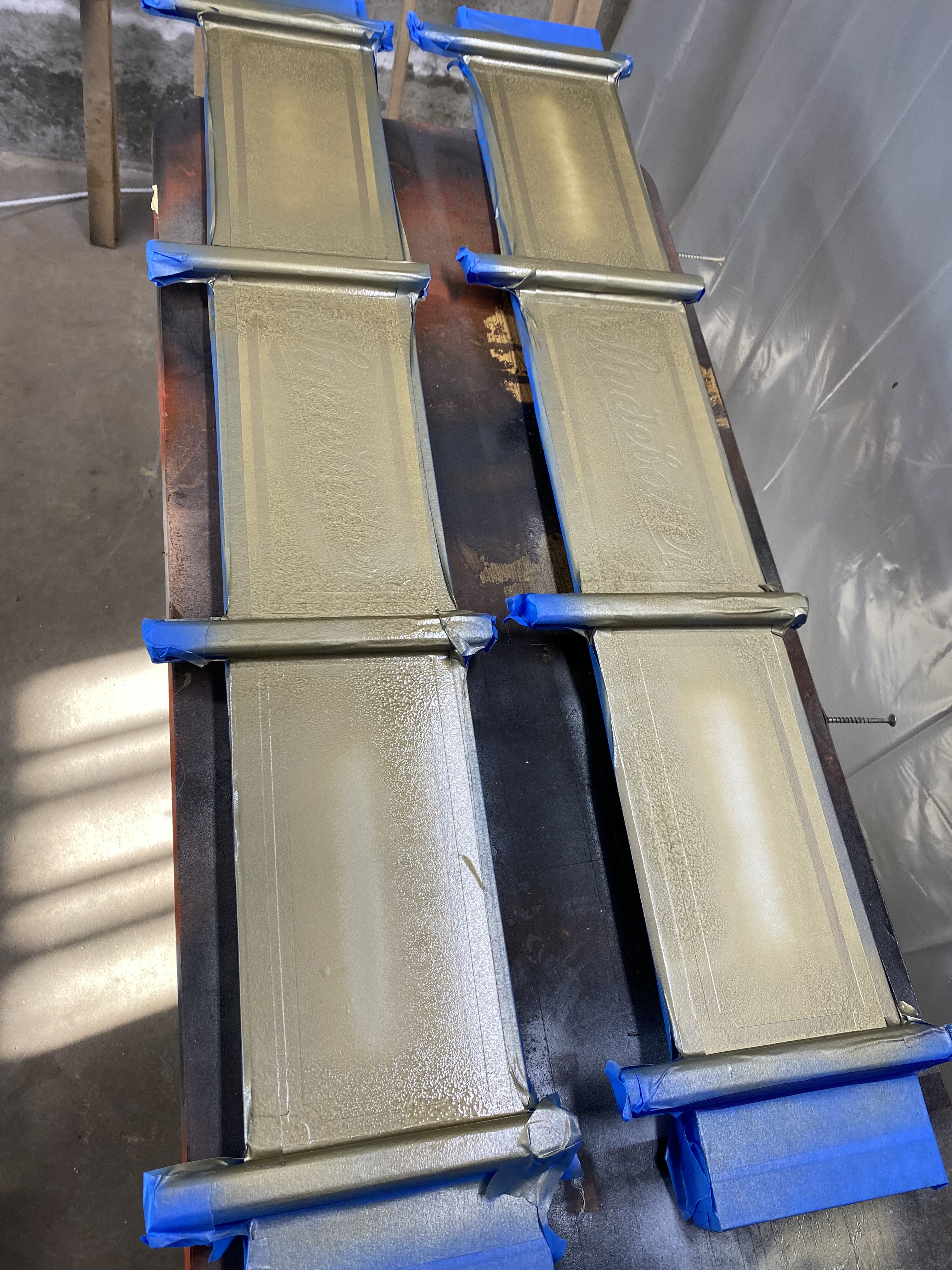

The desired lettering on the wagon could have been done a few different ways. Another one my client had made was just vinyl cuts adhered to the finish, which was not a way I wanted to go. It came down to gold leafing or paint. Considering that the stencil would have to be made either way, I found a decent rendering of the logo online, converted it to a vector image, save the files at the size I needed and had a friend fire them off on his plotter at his print shop. Where that couldn’t be done, I free handed the masking. Out of cost consideration, I decided to go with Rustoleum Hammered Gold paint over gold leaf. This was applied after sealer coat and 1st coat.

The paint took well, though there were a few places the masking took a few little chips. Those were touched up and 2 more coats of poly were applied.

All the metal was either electro-galvanized or painted black. The only place there were issues were with the tires which came assembled onto the wheel. Masking forwards and backwards left some crappy marks on the paint that needed to be polished out. Otherwise though, it went really well!