Custom Job has been working hard to get its metal shop at least up to snuff with its wood working capacities.

This month we added an antique O. & N. Peck bead roller, a PEXTO 62-C 21″ 22ga brake and a Wissota E-6 6” Bench Grinder.

The Wissota, while not necessarily a Baldor or any number of other higher end machines if it’s day was just like any other standard bench grinder and still is. If it’s in a room with oil in the air, it probably still runs fine. I needed a bench grinder as I’ve been getting by with using stones and wire wheels on my shopsmith.. in my wood shop Way way way to close to finishing surfaces. It had a certain charm about it and the price was right… plus it came with on a base of enough wood to heat the house for a few days once I build a better one!

The brake was pretty much plug and play after wrestling it down out of the truck. The 45 and 90 deg. stops appear to be a little off and will need to be rebuilt but otherwise … The paint sucks. I’ll live.

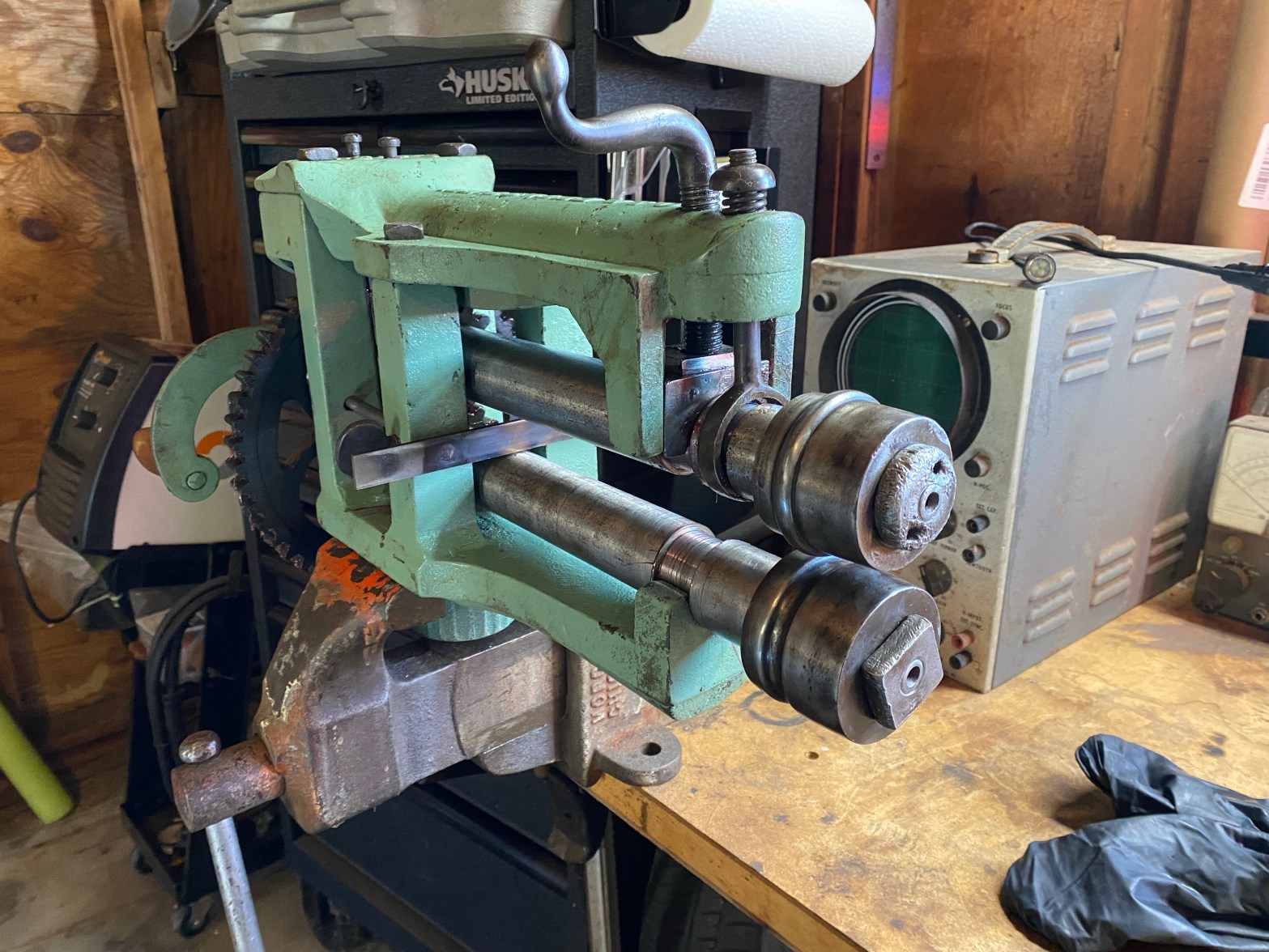

The bead roller was another story all together….

Obviously, aside from weighing slightly more that a newer, smaller model with a handy dandy clamp on base, a hundred some odd year old tool is bound to have issues. A few were apparent, like the folded up tin making up for the wear in upper bearing adjustment and the (roughly) 5/16-14 threading on the roll nuts (built before thread standardization so everything was some strange pitch that won’t be in your average tap and die set).

The crank handle was also an issue. Aside from the original wooden handle being covered in duct tape (I stripped, sanded and coated it in epoxy resin) or whatever reason, both the handle and the arbor was threaded making it impossible to properly tighten the handle. Too, it was threaded in some strange bastard thread. So I over bored the arbor and recut the threads in the handle to good ole 5/16-18 and grabbed a sorta correct looking square head bolt for it.

The roll nuts were mismatched but again, I wasn’t going to find anything to replace them with those threads. I just cleaned them up and reused them. There was however a busted off key on the roll spindle. Luckily I was able to extract what was left and reuse the keyway after I made a new key.

The “internal” gears were held in place on the shafts by like, gauges in the shaft just behind the gear. On the upper shaft this had worn away so that whenever you drive the mechanism, the heat would slide backwards and out of contact with the heat below it. I wound up cutting a groove behind the gear around the diameter of the shaft and using a 1” retaining clip.

I wasn’t entirely sure what the little 5/16 holes with the wing nuts was for but I assume it was some sort of guide. I had some coil stock left over from an old project and some 5/16” rod which I welded together to make the guide.

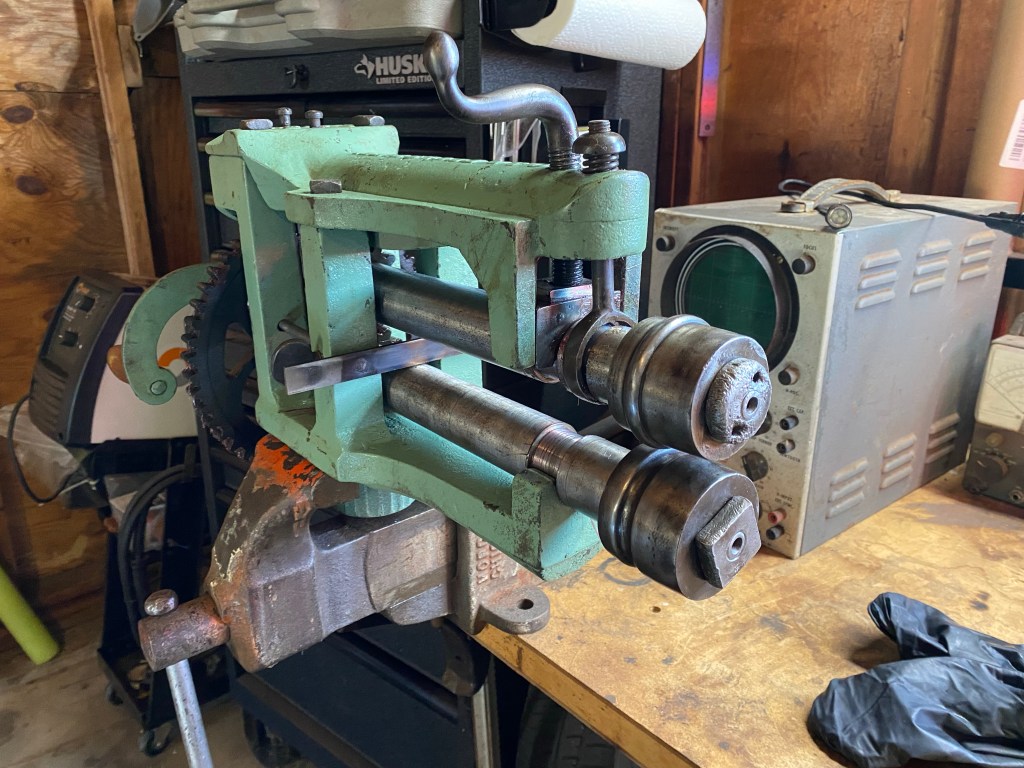

From the looks of it, it works well (horizontal stripes on top are from before the rebuild, vertical on the left from after).Even with some seriously worn dies, it tracks straight and easily deals with the thinner stuff. I’m hoping I can find some more dies that will work with it… if not, I’m sure I can make some.. you know, after I fix up a lathe? Maybe a Bridgeport?

On that subject, welding capacity should be up to 1/4” materials this spring. I’m still looking for a decent drill press, some gas cans and a table for welding and a different compressor. Unfortunately, money is like space. Just not enough of either…. Maybe that’s actually fine.